SPRAY DRYER PRESSURE NOZZLE

Pressure nozzle

atomization can be the best choice for many spray drying applications for reasons

such as producing a narrower particle size distribution, a

larger average particle size is required (> 100 micron), better control of

spray dryer wall buildup, and lower overall capital, energy, and maintenance costs of the spray dryers. The inserts for these nozzles

are typically made of tungsten carbide and wear out over time (the orifice becomes too large), and must be replaced

to maintain proper atomization and spray dryer performance. The rate of wear, and the frequency of replacement of these inserts, depends upon the

type of feed being sprayed, as well as the spraying pressure.

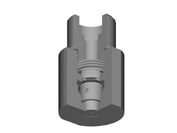

Below is the SDS "O" Series spray dryer pressure nozzle,

with

tungsten carbide wear

parts (Orifice Insert and Swirl Chamber):

Lance Adaptor

Part#

90004T |

|

|

Retainer Key

Part# 90006 |

Screw Retainer

Part# 90005 |

|

|

Assembled Nozzle |

Swirl Chamber

Part# 90001 |

|

Orifice Insert

Part# 90002 |

|

Chamber Housing

Part#

90003 |

|

|

|

"O" Series Spray Dryer Pressure Nozzle Sketch

"O" Series

Spray Drying Pressure Nozzle

Cut Sheet

Pressure Nozzle Inserts (Swirl Chamber and Orifice Insert)

- Hollow cone spray for optimum spray drying results

- Uniform droplet distribution for the most narrow product particle size distribution

- Full size range of orifice inserts and swirl chambers for

a wide range in flow rates, spraying pressures, and spray angles

-

Available in “A” carbide for superior wear resistance for

non-corrosive, abrasive fluids

-

Interchangeable with the Whirlchambers and Orifice Inserts for the Type 104 and SSTC WhirlJet SprayDry nozzles

from Spraying Systems Company

Pressure Nozzle Body Parts (Chamber Housing, Lance Adaptor, Screw Retainer)

- Different alloys for mating threaded components minimize galling problems

-

Gasket-less design for most slurries containing undissolved

solids

- Spraying pressures up to 5,000 psig

Please call SDS @ 410-549-8090 for additional information on our

spray dryer pressure nozzle.

Back to Top

|